It’s long been said children’s minds are the future. Little Inventors is a creative and educational organization that inspires imagination and takes this concept seriously. Born from creative minds in the United Kingdom Little Inventors creates free resources for institutions, teachers, and parents to encourage children to think up and draw innovative inventions. From these ideas, they promote challenges, events, and workshops. In addition to encouraging promising young inventors, they encourage skilled experts and makers, like Fori Automation, to work with local children to turn their ideas into reality. Making the fantastical practical.

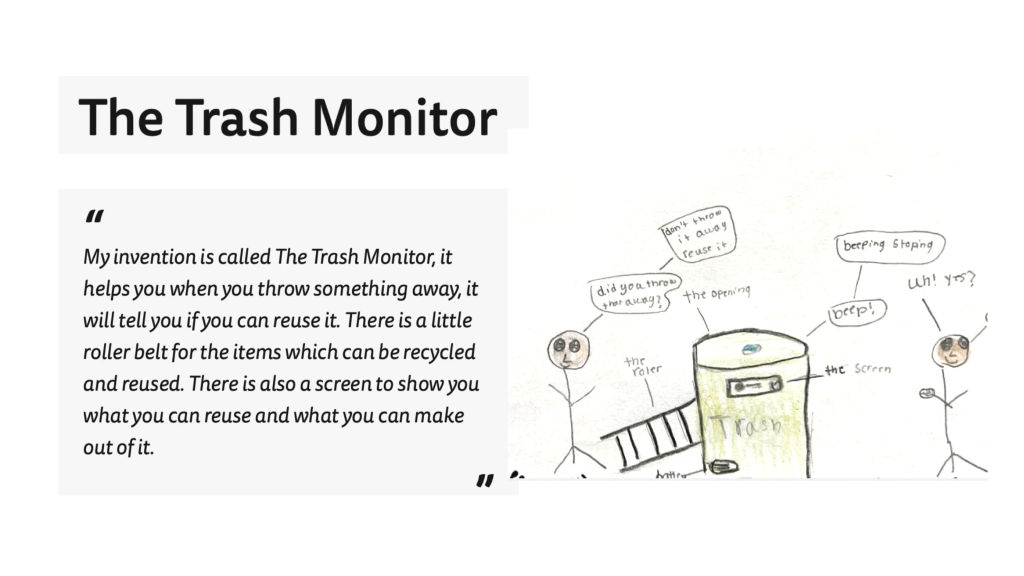

This year MISD the Macomb County chapter of Little Inventors brought some of these great inventions to reality, with students from around southeast Michigan. Fori jumped at the opportunity to work on a design by New Baltimore student Sa’Niya. Sa’Niya’s brilliant idea tackles the problem of trash and asks people to take a harder look at what they are throwing away. Her design is called the Trash Monitor. The concept helps people discern if what they are throwing away is trash or if it can be reused or have another purpose.

To start this project the Fori team dove into the world of recycling. As an automation company, we had an idea of how we would bring Sa’Niya’s Trash Monitor invention off the page, but we needed to learn more about recycling and the materials the project would filter.

Many products and items that we throw away can easily have a second, third, or fourth life and we were excited to conceptualize this design which helps people identify items that are not – at first glance – trash.

After completing our recycling research, we moved on to sourcing the parts we would need for the Trash Monitor and creating the design. We had to find a trash receptacle we could modify and sensors to detect various items of materials that are commonly thrown away.

Sa’Niya’s idea for the trash monitor is when someone drops what they think is a piece of trash into the Trash Monitor receptacle, the sensors in the bin detect if the item is trash or if it can be reused or is a recyclable material. If the item can be recycled or reused it moves onto the conveyor and back to the user. If the item is truly trash it stays in the bin. Additionally, if an item is recyclable, a Trash Monitor alerts the user with a buzzing noise and the recycling symbol lights up bright green.

Many of the parts on the project such as the project logo, recycling logo, and conveyor could be 3D printed in our shop, here in Shelby Twp., Michigan. One of our mechanical engineers who specializes in 3D printing, created a design concept for the overall project using CAD software and designed the conveyor model as well.

Another final aspect of the Trash Monitor is the information panel on the front of the bin. A screen is attached to the receptible, this informational screen helps the user learn more about waste, recycling, and how we can all make small changes for a better community and world in relation to what we throw away.

Several Fori teams, including mechanical engineering, controls engineering, marketing, human resources, and the manufacturing shop came together to work on this project. Everyone involved truly enjoyed the opportunity to exercise their creative muscles and bring Sa’Niya’s sensational invention to life.

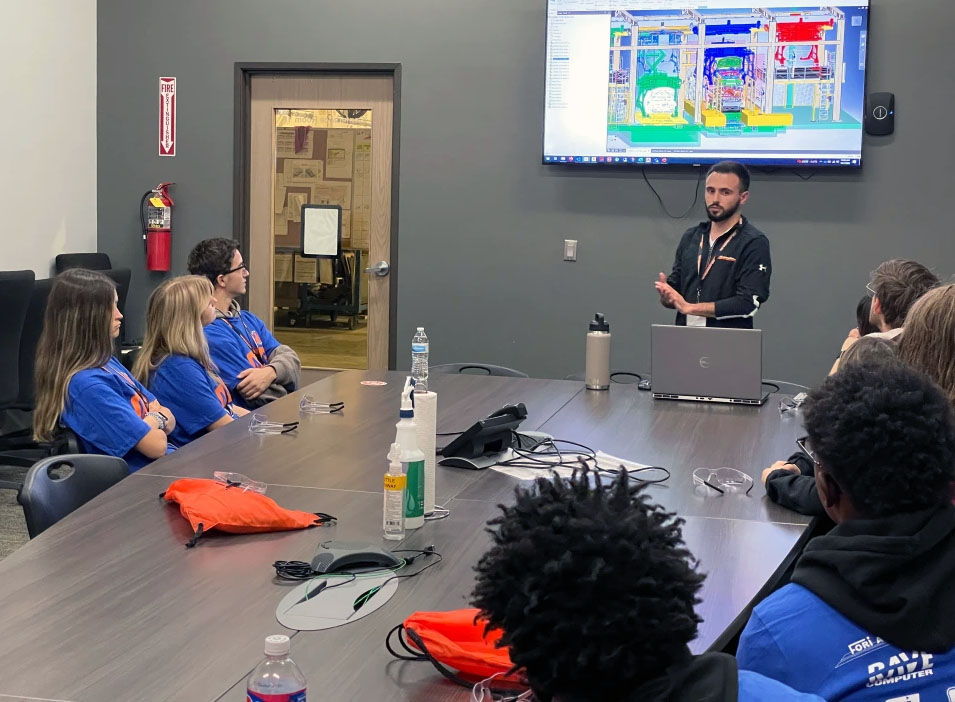

In the images, you can see the final CAD design for the project along with one of our engineers wiring a board for the receptacle sensors. One of the reasons we liked this design was its practicality and how we can see it used today in many applications from a school hallway to an office complex or a bustling city center.

With the Trash Monitor complete, we were proud to showcase Sa’Niya’s design at the Macomb County Little Inventors banquet, along with other student inventors and makers. This project was truly an inspiration to Fori and our team. We hope all the Little Inventors continue to use their minds and imagination to create amazing inventions for a brighter and greener future.